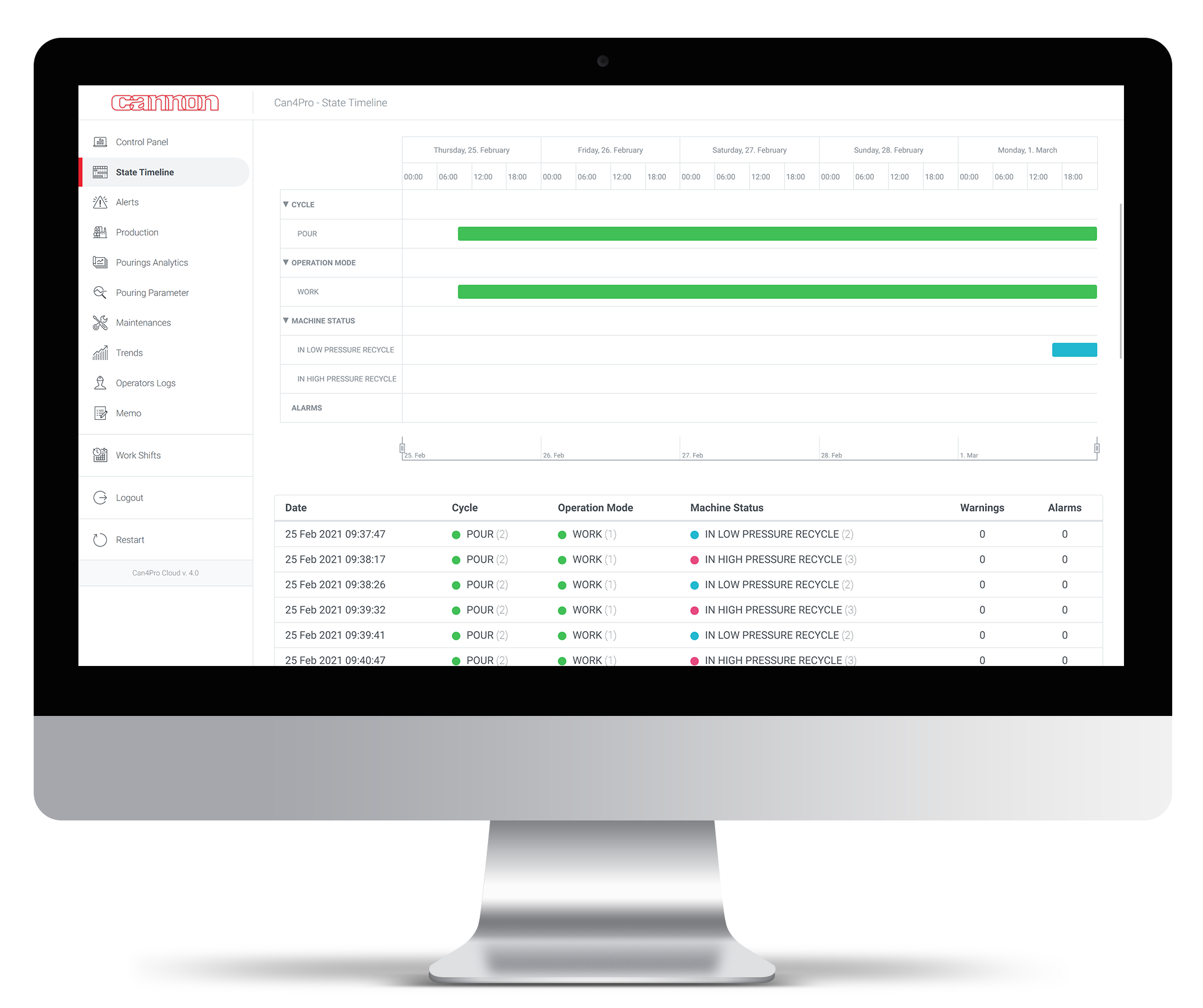

Availability

It shows the time of each machine status and of each of its work cycles in order to determine the actual availability of the machine.

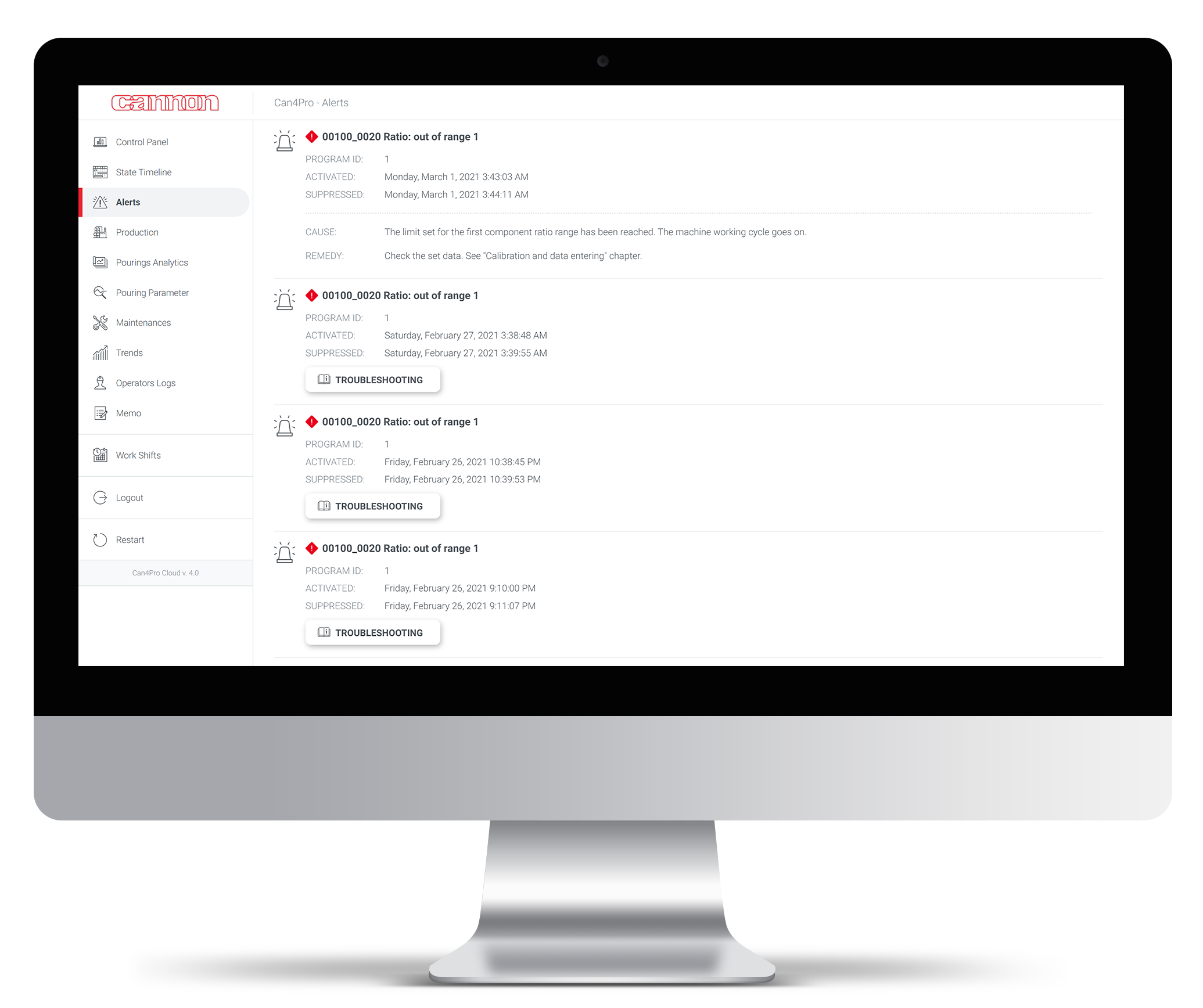

Alarms

Machine warnings and alarms are promptly notified at the interface level. Possibility to download them in Excel format. Troubleshooting in line with causes and remedies.

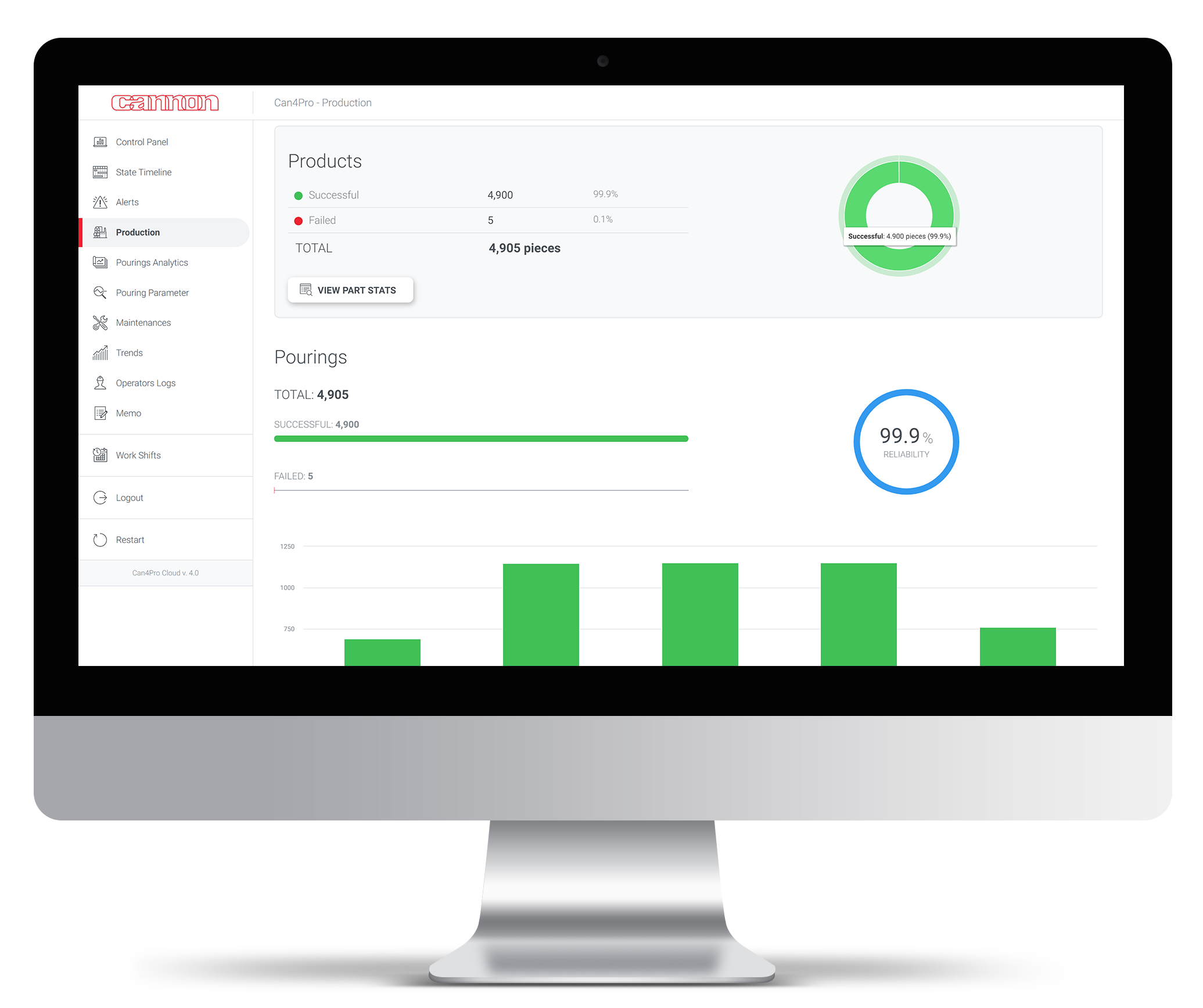

Production

It monitors the castings / pieces (total, successful and unsuccessful), calculates a reliability index and relates them to the consumption of the components.

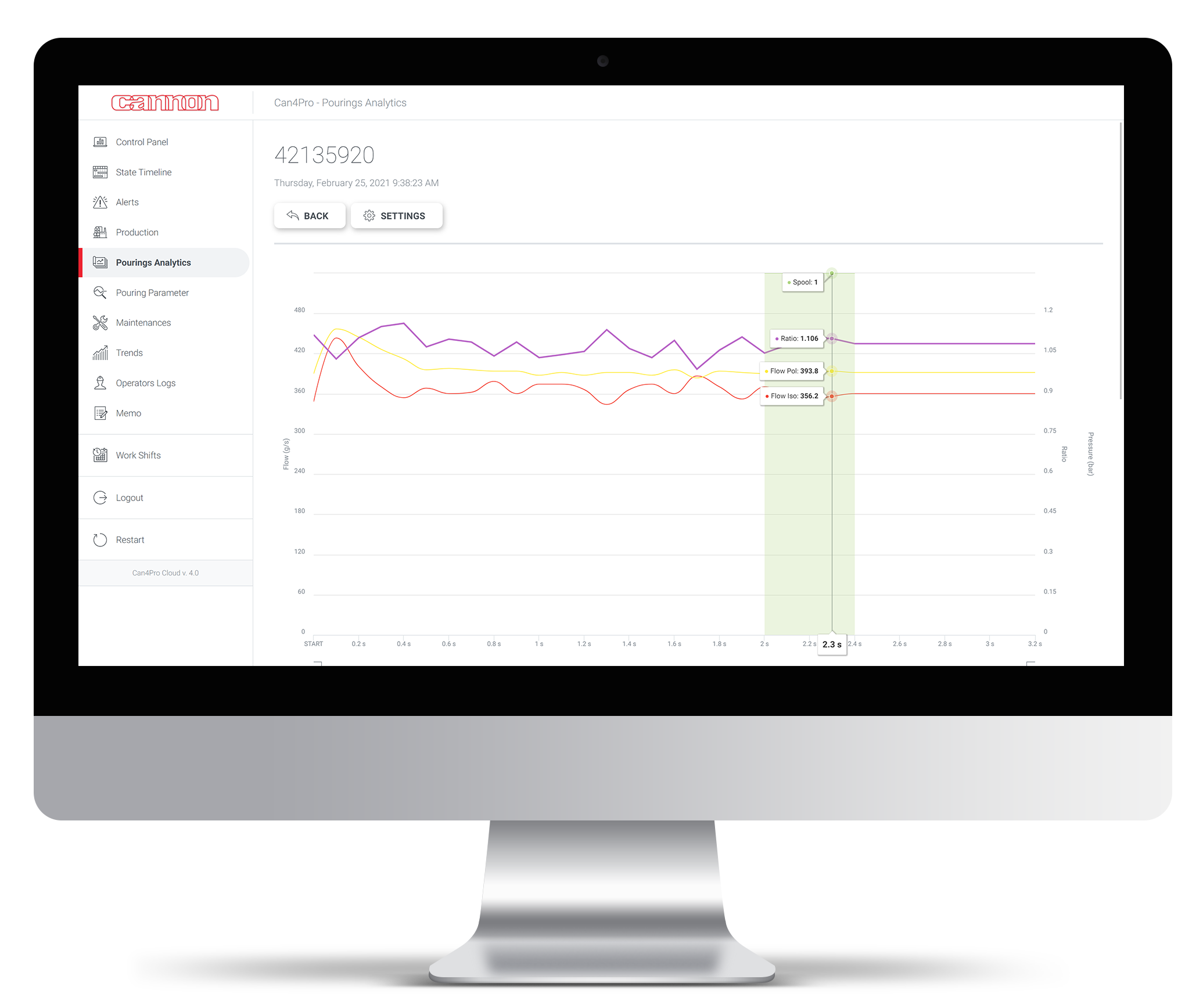

Analysis of the pourings

It allows you to graphically analyze the behavior of the most significant casting data, sampled with an interval of 100 ms.

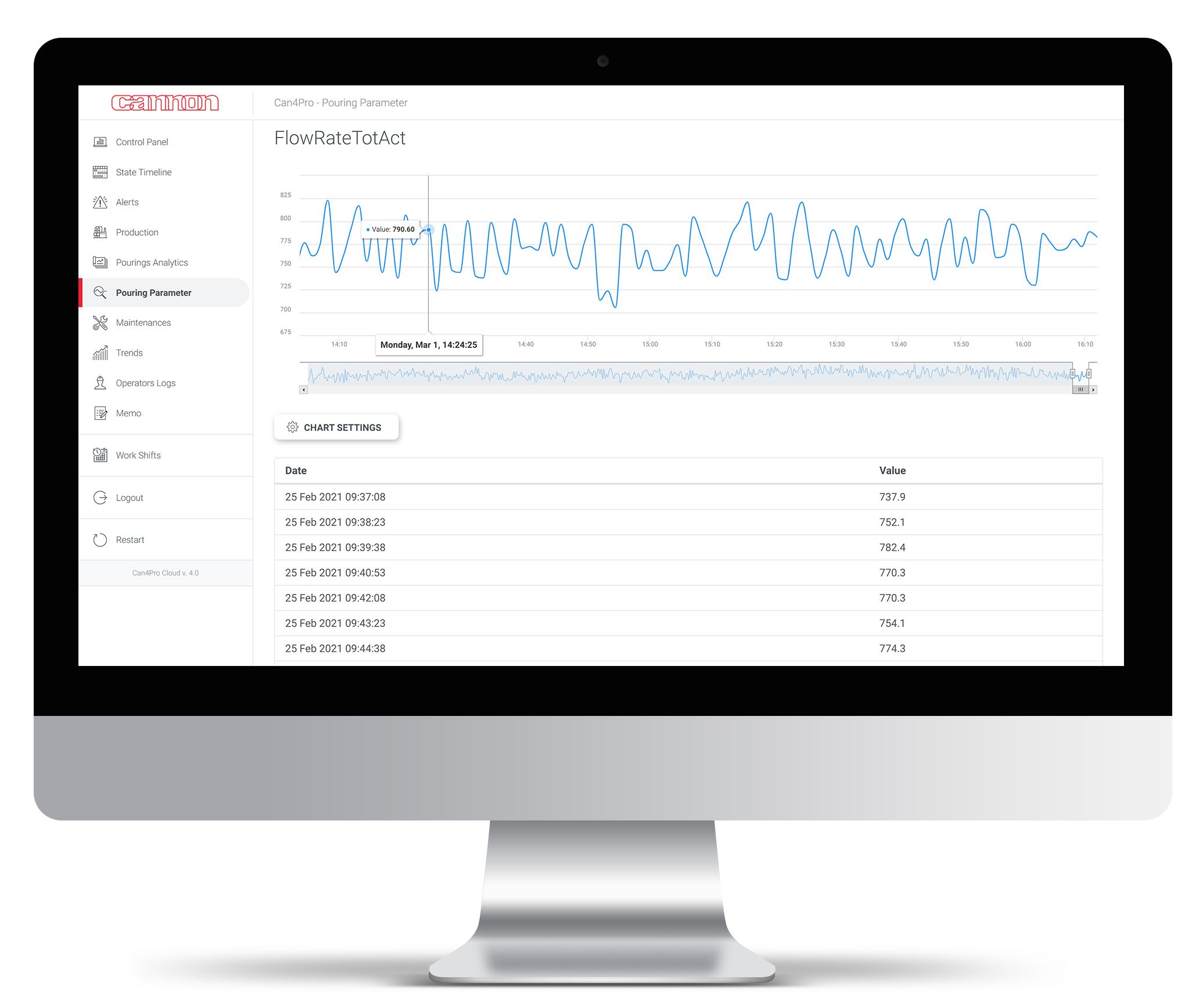

Analysis by parameters

It allows you to graphically analyze the trend over time of a specific casting parameter, filtering by recipe, head, casting, etc.

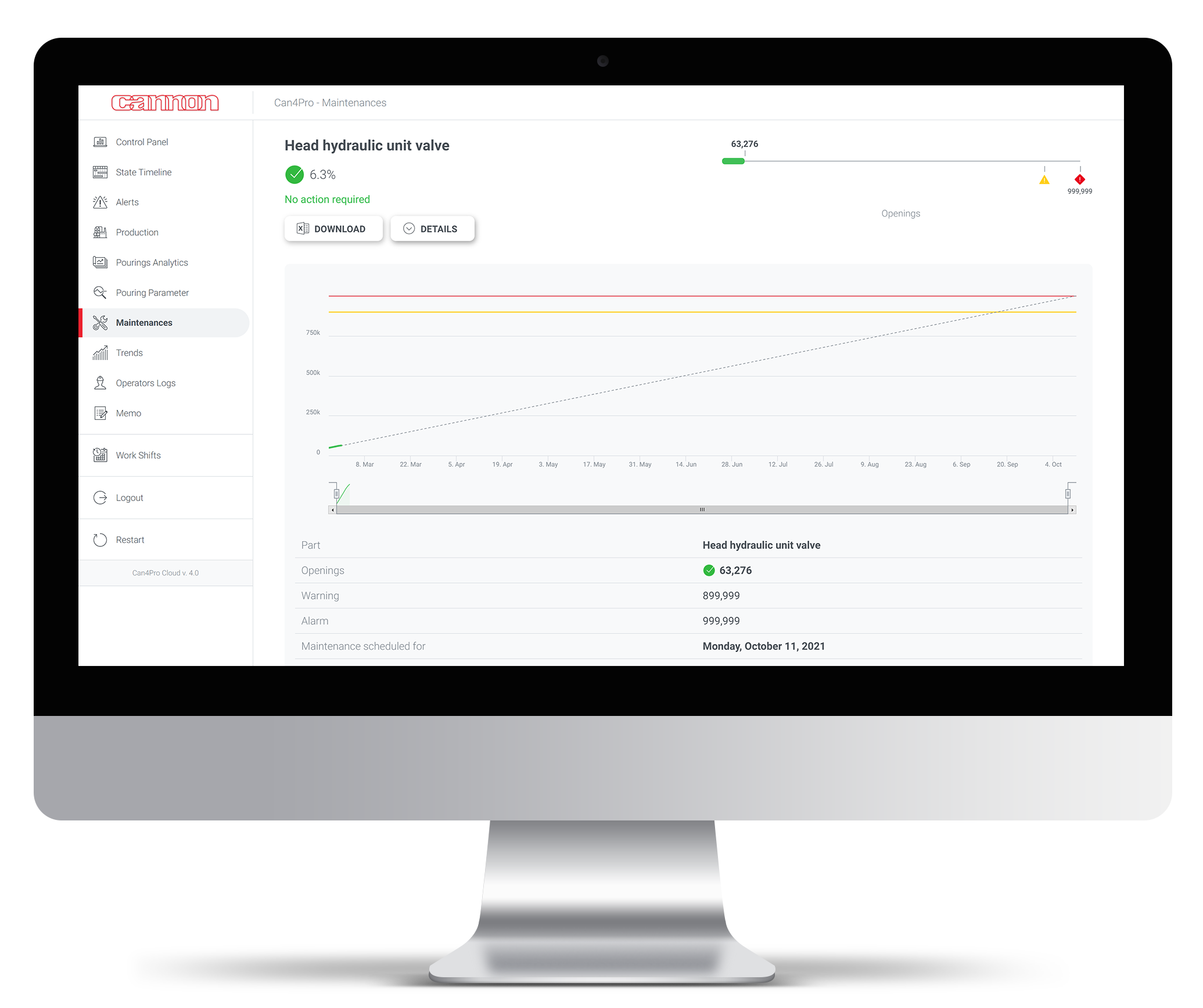

Maintenance

It allows you to plan in advance the necessary maintenance interventions so as to minimize downtime.

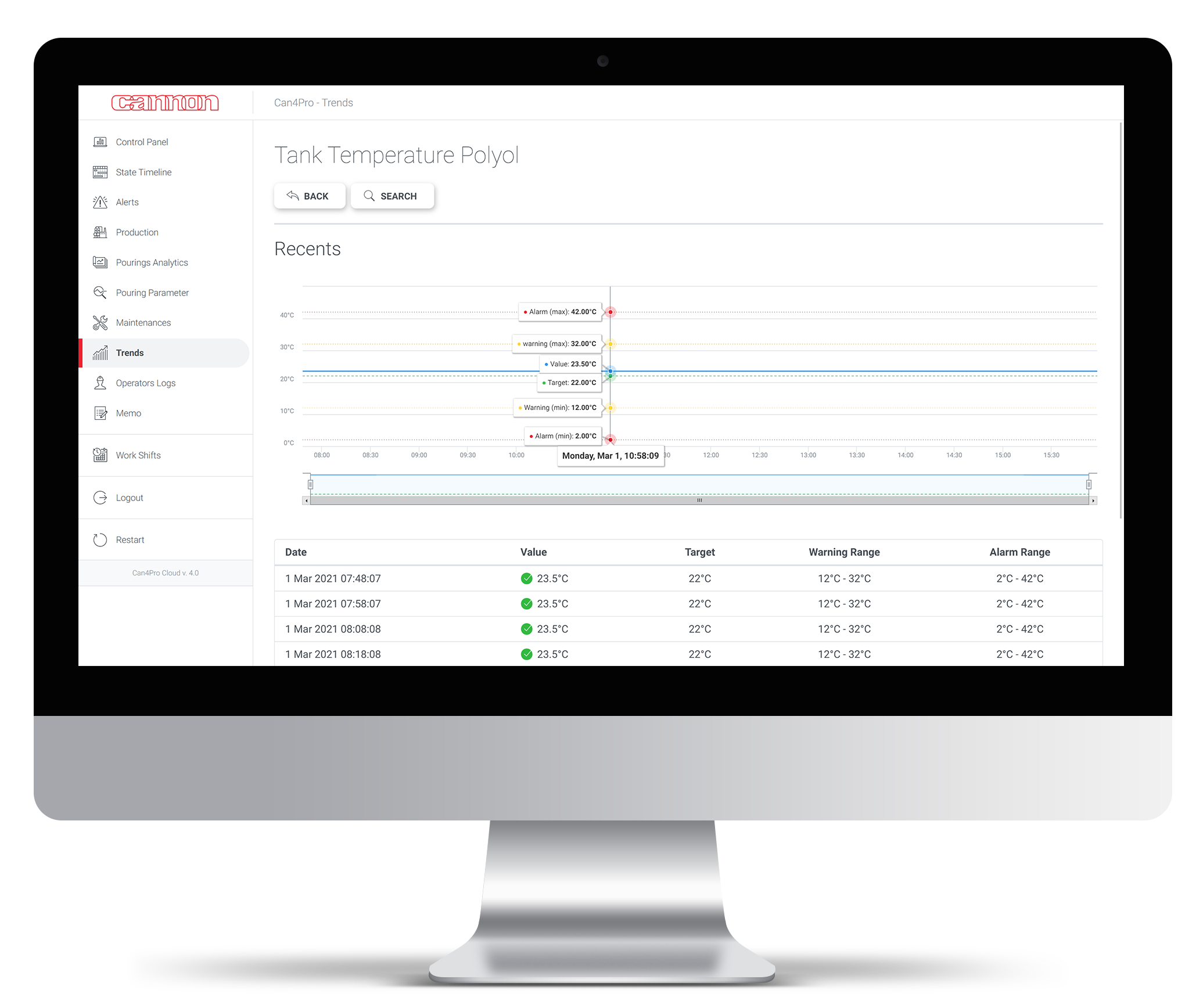

Trends

Records the temporal trend of significant parameters for the machine such as the temperature of the material storage tanks.

Memorandum

A convenient bulletin board where you can take notes or leave notes for the operator / maintenance technician.

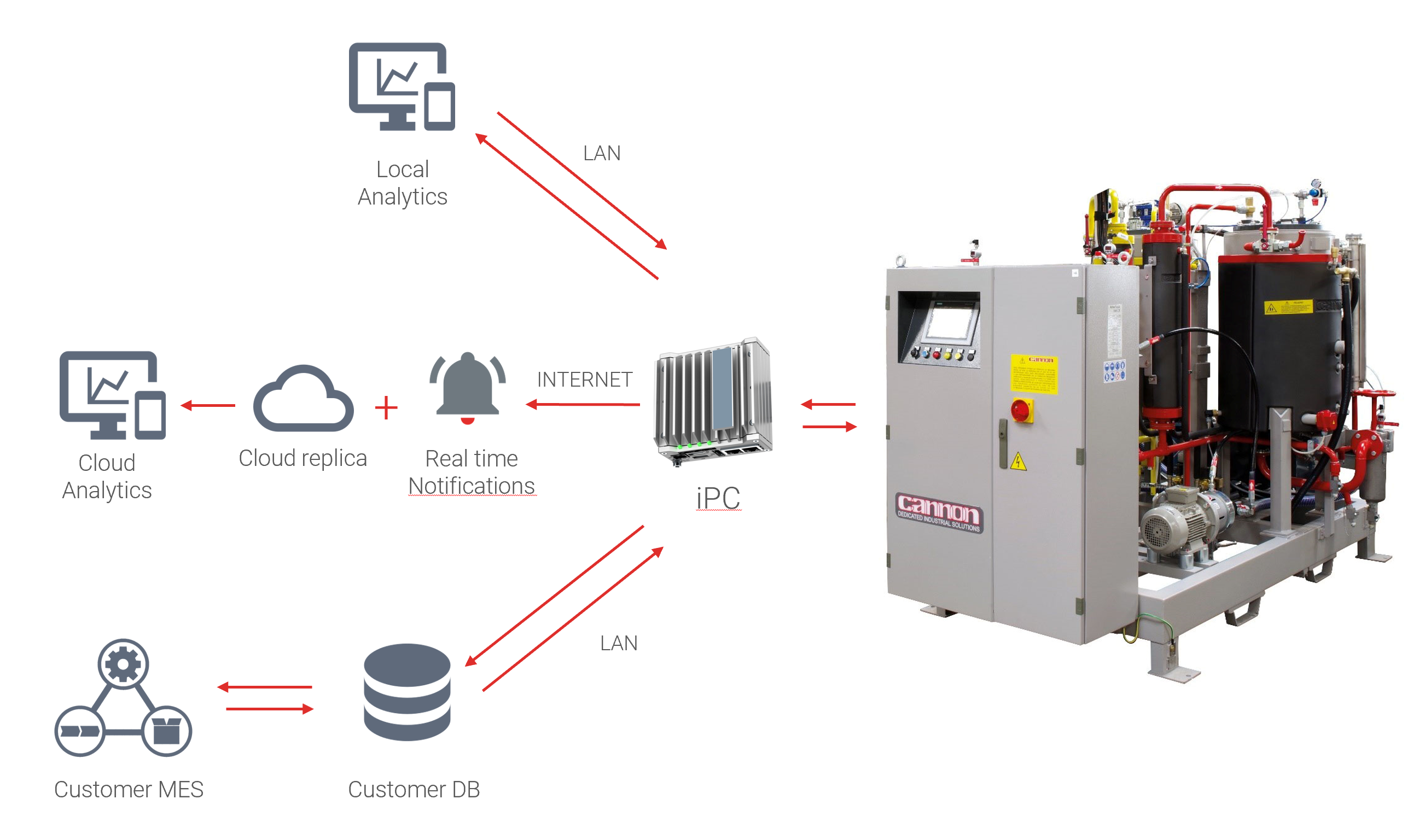

Remote PO

Allows the sending of recipes / production orders remotely to the machine. The production output can be published by Can4Pro in an external customer DB or reside on the iPC.

This function complies with the interconnection requirements of the plant with the company system in order to obtain the tax credit provided for by the national Transition 4.0 plan

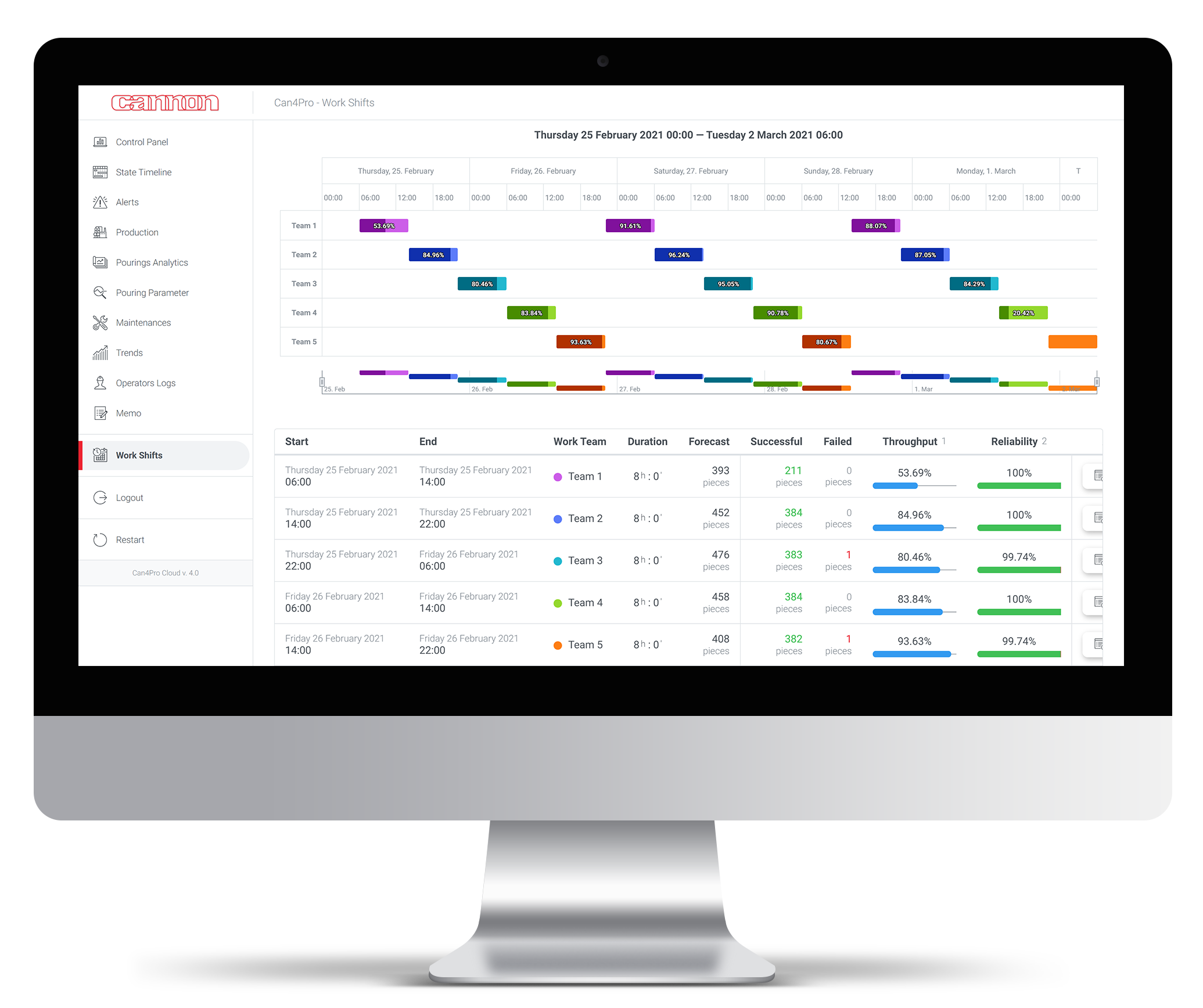

Work shift

It is now possible to create work teams and plan shifts. By indicating the forecast of pieces to be produced per shift, it is possible to obtain performance indicators (eg. OEE)

Cloud replica

It allows you to replicate all data on the iPC in a cloud space (AWS) to make it accessible from any device with an internet connection, using your credentials.

Customizations

Customizable platform with features on customer request.

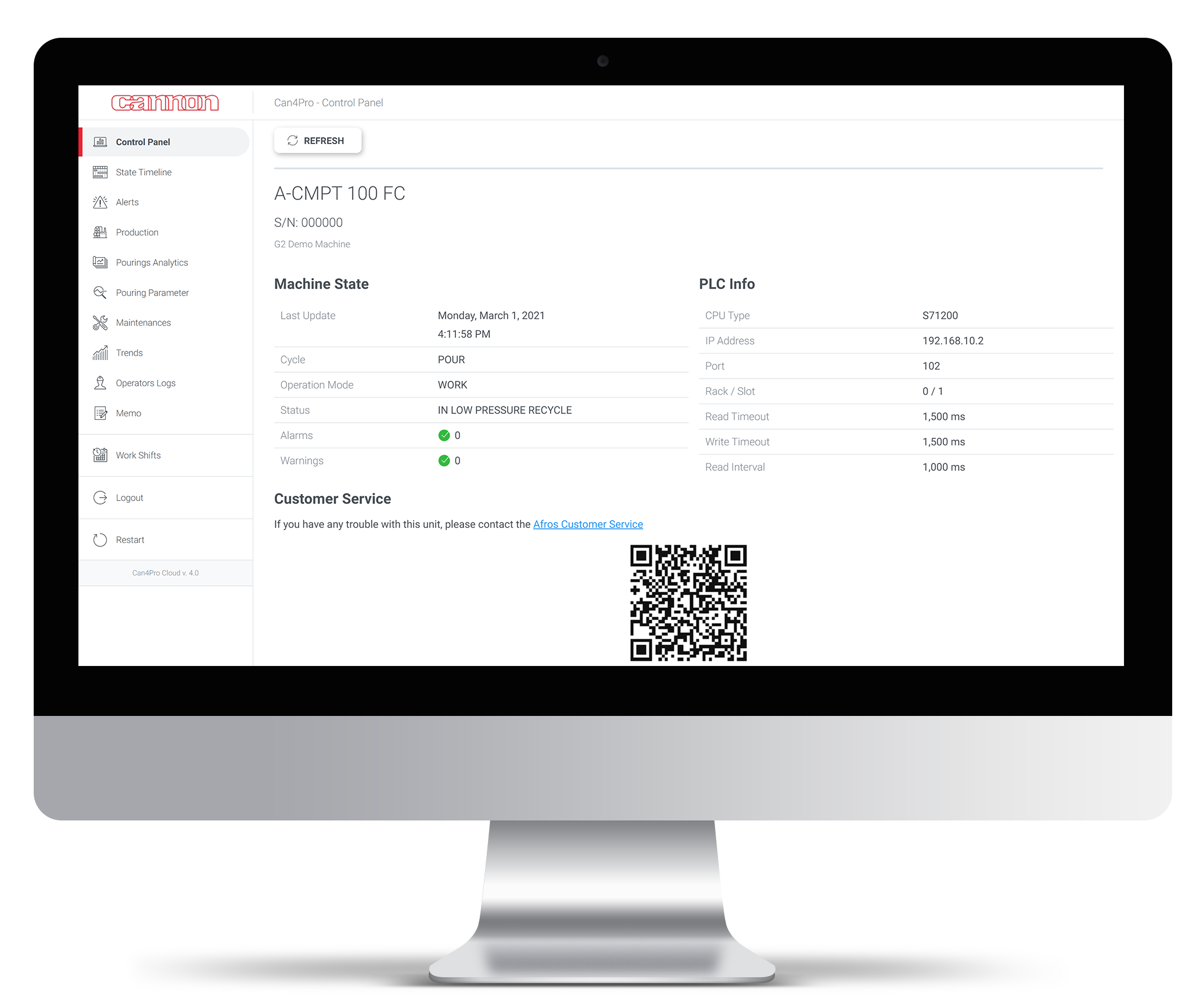

Machine status

With a single glance it is possible to check the status of the machine by evaluating the main parameters: machine status, work cycle, alarms, maintenance, etc.

Assistence

By framing the QR-Code present in the main Can4Pro dashboard, you access the dedicated site to which the serial number of the machine and the geolocation of the request are automatically passed.

Real-time notifications

It is possible to receive push notifications of the main events (eg alarms, warnings, maintenance, etc.) through a Bot developed for the Telegram platform. To receive them, simply install the Telegram app and frame the QR-code present in Can4Pro.